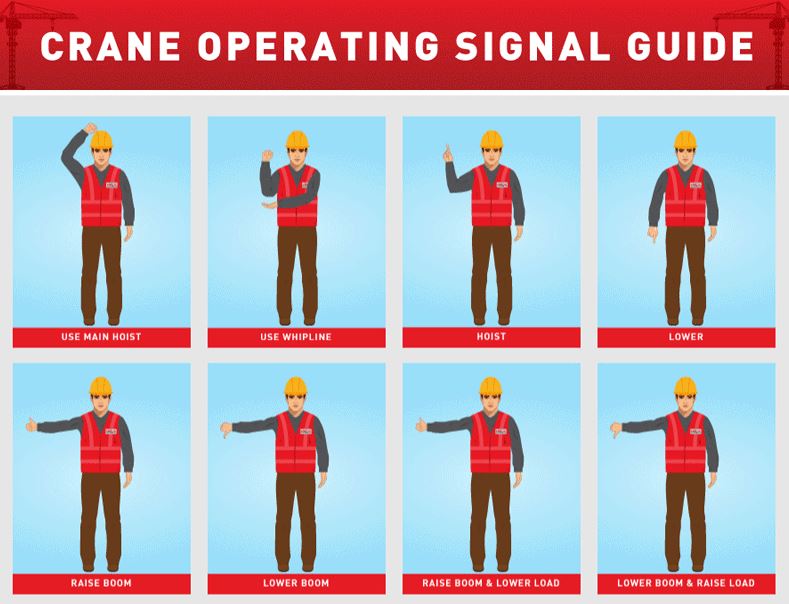

CRANE OPERATOR HAND SIGNAL GUIDE

Crane operation is a team effort. To be safe and successful, the operator and on-ground support crew must have a clear, standardized, and efficient means to communicate. Electronic devices work well but having a ‘no-tech’ backup means of communication – like hand signals -ensures the team will always have a way to stay in touch.

Crane Service, Inc., offers this animated crane operator hand signal guide which is based on the American Society of Mechanical Engineers (ASME B30.17-1992) crane operator conduct and safety standard.

On construction sites, one of the most important jobs is that of the signal person. This person is responsible for signaling the crane operator with orders for the lift. To accurately and safely direct crane operators, the signal person must know and understand the operation signals used in the ASME 1926 regulations. The signal director must also understand the operations and limitations of the equipment they’re directing, such as the crane’s dynamics involved in swinging, raising, lowering loads, stopping loads, and boom deflection.

OSHA regulations require a signal person must be present on the job site when the load or area near the load is not in full view of the operator, when the equipment will need to move throughout the job and the direction of movement is obstructed, or when the operator or site manager believes a signal person should be present because of site safety conditions.

Hand signals offer advantages where radios or other electronic devices fall short. Such as:

- Clarity – Standard hand signals minimize ambiguity because the signal person can only “speak” using signals, or a combination of signals, directly related to the crane controls.

- Speed – Visual signals are immediate. A skilled signal person can develop the ability to signal faster than the human tongue can form words.

- Distance – Verbal directions can be delayed, misheard or misunderstood depending on an electronic device’s distance limitations. Hand signals eliminate this issue.

- Noise – Noise levels at construction sites can be overwhelming and verbal direction becomes lost in the clamor . Workers with or without hearing protection gear on busy sites don’t need to rely on their hearing ability when using hand signals to communicate.

- Continuity – Hand signals are a ‘common’ language and will communicate a specific direction no matter what languages are spoken on the worksite.

Hand signal guidelines:

- All lifts should employ a qualified signal person with knowledge of standard hand signals

- Ensure that the signal person and the driver/operator agree on hand signals before beginning

- The signal person should always maintain visual contact with the driver

- Drivers/operators should stop movement immediately if they lose sight of the signal person

- Provide the signal person with high-visibility clothing, especially during night operations

Accidents happen when hand signals are misunderstood or misinterpreted, so it is imperative the operator and signal person take the time to study and memorize the necessary signals.

Help your employees learn and review these signals to stay safe on your worksites.

Source: Crane Service Inc. http://www.constructionequipment.com/crane-operator-hand-signal-guide